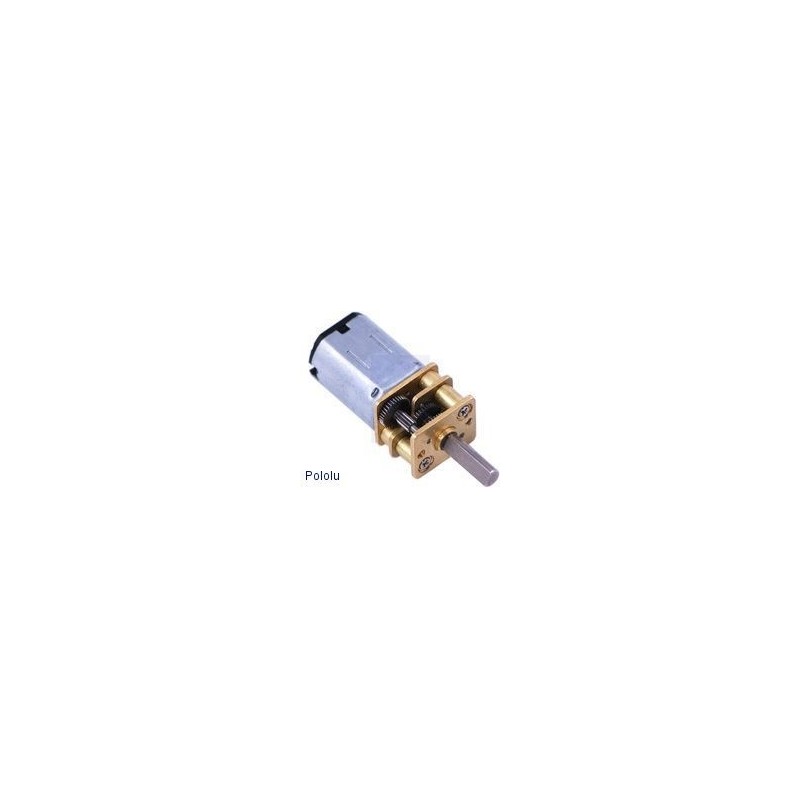

10:1 Micro Metal Gearmotor MP

Politiche per la sicurezza (modificale con il modulo "Rassicurazioni cliente")

Politiche per la sicurezza (modificale con il modulo "Rassicurazioni cliente")

Politiche per le spedizioni (modificale con il modulo Rassicurazioni cliente)

Politiche per le spedizioni (modificale con il modulo Rassicurazioni cliente)

Politiche per i resi merce (modificale con il modulo Rassicurazioni cliente)

Politiche per i resi merce (modificale con il modulo Rassicurazioni cliente)

These tiny brushed DC gearmotors are intended for use at 6 V, though in general, these kinds of motors can run at voltages above and below this nominal voltage, so they should comfortably operate in the 3 – 9 V range (rotation can start at voltages as low as 0.5 V). Lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor. The micro metal gearmotors are available in a wide range of gear ratios—from 5:1 up to 1000:1—and offer a choice between three different motors: high-power (HP), medium-power (MP), and standard. With the exception of the 1000:1 gear ratio versions, all of the micro metal gearmotors have the same physical dimensions, so one version can be easily swapped for another if your design requirements change. Please see the micro metal gearmotor comparison table for detailed specifications of all our micro metal gearmotors. This dynamically-sortable table can help you find the gearmotor that offers the best blend of speed, torque, and current-draw for your particular application. A more basic comparison table is available below.

Some versions of the gearmotors are sold with an additional 1mm-diameter output shaft that protrudes from the rear of the motor. This 4.5mm-long rear shaft rotates at the same speed as the input to the gearbox and offers a way to add an encoder, such as our magnetic encoder for micro metal gearmotors, to provide motor speed or position feedback.

| Motor Type | Stall Current @ 6 V | No-Load Speed @ 6 V | Stall Torque @ 6 V | Gearbox Shaft Only | Gearbox & Motor Shafts |

|---|---|---|---|---|---|

| high-power (HP) |

1600 mA | 6000 RPM | 2 oz-in | 5:1 micro HP | |

| 3000 RPM | 4 oz-in | 10:1 micro HP | 10:1 micro HP | ||

| 1000 RPM | 9 oz-in | 30:1 micro HP | 30:1 micro HP | ||

| 625 RPM | 15 oz-in | 50:1 micro HP | 50:1 micro HP | ||

| 400 RPM | 22 oz-in | 75:1 micro HP | 75:1 micro HP | ||

| 320 RPM | 30 oz-in | 100:1 micro HP | 100:1 micro HP | ||

| 200 RPM | 40 oz-in | 150:1 micro HP | |||

| 140 RPM | 50 oz-in | 210:1 micro HP | |||

| 120 RPM | 60 oz-in | 250:1 micro HP | |||

| 100 RPM | 70 oz-in | 298:1 micro HP | 298:1 micro HP | ||

| 32 RPM | 125 oz-in | 1000:1 micro HP | |||

| medium-power (MP) |

700 mA | 2200 RPM | 3 oz-in | 10:1 micro MP | 10:1 micro MP |

| 730 RPM | 8 oz-in | 30:1 micro MP | |||

| 420 RPM | 13 oz-in | 50:1 micro MP | |||

| 290 RPM | 17 oz-in | 75:1 micro MP | 75:1 micro MP | ||

| 220 RPM | 19 oz-in | 100:1 micro MP | 100:1 micro MP | ||

| 150 RPM | 24 oz-in | 150:1 micro MP | |||

| 75 RPM | 46 oz-in | 298:1 micro MP | |||

| low-power | 360 mA | 2500 RPM | 1 oz-in | 5:1 micro | |

| 1300 RPM | 2 oz-in | 10:1 micro | |||

| 440 RPM | 4 oz-in | 30:1 micro | 30:1 micro | ||

| 250 RPM | 7 oz-in | 50:1 micro | 50:1 micro | ||

| 170 RPM | 9 oz-in | 75:1 micro | |||

| 120 RPM | 12 oz-in | 100:1 micro | 100:1 micro | ||

| 85 RPM | 17 oz-in | 150:1 micro | |||

| 60 RPM | 27 oz-in | 210:1 micro | |||

| 50 RPM | 32 oz-in | 250:1 micro | |||

| 45 RPM | 40 oz-in | 298:1 micro | 298:1 micro | ||

| 14 RPM | 70 oz-in | 1000:1 micro |

Note: Stalling gearmotors can greatly decrease their lifetimes, occasionally resulting in immediate damage to the gearbox. This is especially true for the higher gear ratios, such as the 298:1 and 1000:1 versions, which can generate enough torque to damage themselves. The stall torque values given for the two 1000:1 motors are theoretical, and we strongly recommend you avoid stalling them. Prolonged stalls (on the order of seconds) can result in thermal damage to the motor windings and brushes, especially for the versions that use high-power (HP) motors.

Exact gear ratio: 35×3713×10 ?9.96:1

| Micro metal gearmotor dimensions (units in mm). |

|---|

The gearbox has a long (0.365"" or 9.27 mm), 3 mm-diameter D-shaped metal output shaft, and the brass faceplate has two mounting holes threaded for M1.6 screws (1.6 mm diameter, 0.35 mm thread pitch). The gearmotor weighs approximately 0.35 oz (10 g). Versions with the extended motor shaft have a 1mm diameter round shaft that protrudes 4.5 mm from the rear of the motor, between the two motor terminals; this is not pictured in the above dimension diagram. In terms of size, these gearmotors are very similar to Sanyo’s popular 12 mm NA4S DC gearmotors, and gearmotors with this form factor are often referred to as N20 motors.

The gearbox on the 1000:1 and 1000:1 HP micro metal gearmotors is 12.5 mm long. All of the other micro metal gearmotors have 9mm-long gearboxes, as shown in the above dimension diagram.

|

|

|

|

|

|

|

|

|